Custom mylar bags, those reflective silver wonders, are beloved for their strong barrier properties. They keep moisture out, guard against light, and preserve the freshness of whatever they enclose.

But what if they could also showcase your personality, brand, or unique style? Let’s go on a creative adventure to make distinctive Mylar packaging which stands apart among the competition!

Why Mylar?

- Versatility: Not just a protective shield, Mylar pouches offer a robust canvas ready for your creative touch.

- Durability: Known for its impressive strength, Mylar bag packaging ensures your designs last as long as its protective properties do.

Finding Your Perfect Mylar Bag Manufacturer

Embarking on a custom printed Mylar bag project? Half the battle is teaming up with the right manufacturing partner.

You want someone who understands your vision. Here’s how to find that ideal match:

- Dive into Digital Directories:

- Start by perusing online directories. They’re gold mines for discovering top players in the custom mylar packaging world.

- Trust but Verify:

- A mylar bag manufacturer might have an impressive resume, but what’s their actual track record like? Dig into their history. How long have they been in the Mylar game? Experience often translates to expertise.

- Ask for Show & Tell:

- Samples speak louder than words. Request a few. It’s the best way to gauge their craftsmanship and attention to detail.

- Word on the Street:

- Reviews and testimonials can be incredibly telling. You’re looking for a partner, not just a provider. Who’s raving about their responsiveness, quality, and punctuality?

- Spotlight on Brands:

- Some names pop more than others. For instance, Brandmydispo has made quite a splash in the industry. A manufacturer with a strong reputation usually has a history of satisfied clients backing them.

- Budget Talks:

- While quality should never be compromised, it’s wise to get a ballpark figure. Seek quotes, compare, and remember: sometimes you get what you pay for.

- It’s All About the Vibes:

- How do they interact with you? Are they genuinely excited about your project? Do they get your ideas? The relationship matters. Go with someone who’s on your wavelength.

Remember, the goal is to find a manufacturer who’s not just great on paper but is also a joy to collaborate with. Here’s to crafting customized Mylar bags that truly stand out in the crowd!

Ignite Your Imagination

Picturing your design is the first step. Are you leaning towards bohemian patterns, geometric motifs, or perhaps a minimalist logo? The sky’s the limit! Remember:

- High-resolution images yield the best results.

- Ensure designs reflect the intended purpose. For instance, a quirky design might be great for personal use, but a branded logo works best for businesses.

Design Finalization

- Client Needs: Understand the purpose of the bag – whether it’s for food storage, electronics, pharmaceuticals, or branding.

- Design Review: Scrutinize the design for clarity, resolution, and feasibility. Offer digital proofs before finalizing.

Setting Up the Manufacturing Line

- Material Stock: Ensure a steady stock of the required grade of Mylar.

- Printing Machines: Invest in high-quality printing machines that can accurately replicate intricate designs. Digital printers or specialized rotogravure printing equipment for custom Mylar pouches can be ideal.

- Quality Control Systems: Integrate inspection systems to identify and rectify defects.

Design Implementation Techniques

- Gravure Printing:

- Suitable for bulk orders with a single mylar bag design.

- Ensures uniformity across a large batch.

- Digital Printing:

- Offers flexibility for varying designs.

- Ideal for smaller orders or samples.

Additional Custom Features

- Resealable Zippers: Consider the option of integrating zippers for reusable purposes.

- Transparent Windows: Some might want a transparent patch to view the content. This requires an additional layering process.

- Sizes & Shapes: Customize the pouch bag’s dimensions based on your needs.

Quality Checks & Testing

- Barrier Test: Ensure the printing process hasn’t compromised the bag’s protective features.

- Seal Integrity: Test the seal strength, especially if the bag is meant for food items.

- Visual Inspection: Confirm the design’s fidelity and rectify any inconsistencies.

Client Feedback & Iteration

- After producing a sample batch, collaborate with the client for feedback.

- Modify the design or process based on your input to ensure the final product matches their vision.

Scaling Up Production

- With the prototype approved, initiate bulk production.

- Maintain consistent quality checks to ensure every mylar pouch bag meets standards.

Packaging & Delivery

- Packaging: Ensure custom Mylar bags are packed without any chance of damage or contamination.

- Delivery: Coordinate with logistics for timely and safe delivery, taking into account the delicate nature of the customizable mylar bags.

Tying Everything Together

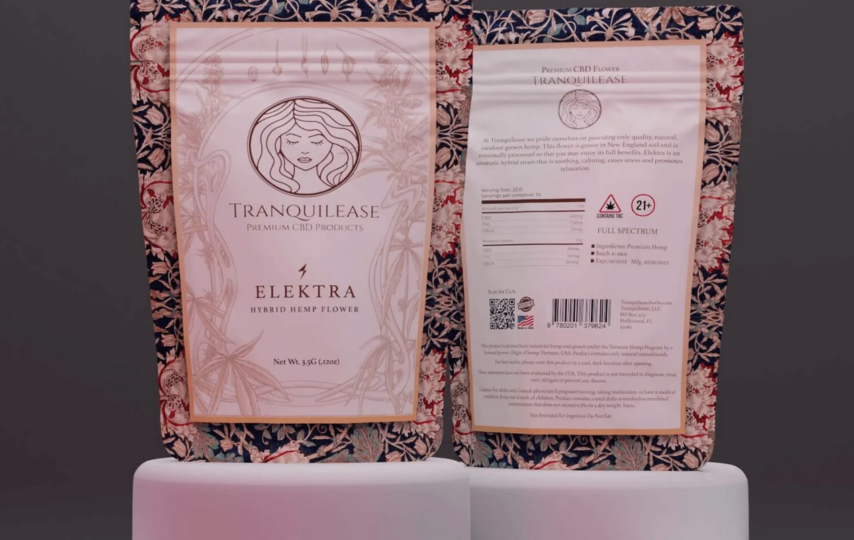

The realm of packaging has seen personalized Mylar bags rise not just as utility items but as canvases of creativity and expression. Whether you’re a brand hoping to leave an impression or someone wanting to add a personal touch, the first step is aligning with the right manufacturer.

True collaboration sparks when there’s mutual understanding and shared enthusiasm. As you embark on this custom Mylar bag adventure, embrace every moment of the creation process. Cheers to crafting distinct Mylar pouch masterpieces that resonate and inspire!