In the dynamic landscape of precision engineering, the need for meticulous attention to detail and the pursuit of technological advancements is paramount. In Perth’s thriving industrial scene, laser cutting stands at the forefront of innovation, offering unmatched precision and versatility. This guide delves into the world of laser cutting services in Perth and the art of material selection to help enthusiasts and professionals alike harness the potential of this cutting-edge technology.

The Intricacies of Laser Cutting Technology

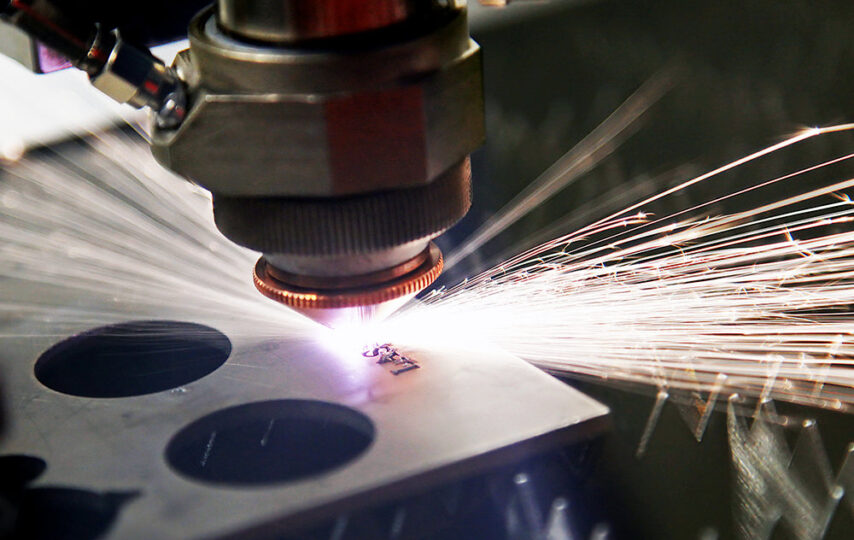

Laser cutting is a sophisticated method that employs a high-powered laser beam to cut materials with precision and finesse. Its versatility allows for various applications, ranging from intricate designs in jewellery making to large-scale industrial projects. The precision of this technology ensures that even the most complex shapes and patterns can be achieved with a fine finish, minimal waste, and high repeatability.

Understanding the Core Advantages

The merits of laser cutting are numerous, particularly when it comes to the accuracy and quality of cuts. Being a non-contact process, it eliminates the risk of material contamination or mechanical distortion. Additionally, the high level of automation and efficiency inherent in laser cutting technology simplifies operations, reducing labour costs and turnaround times.

Tasks Suited for Laser Cutting

Laser cutting serves a broad spectrum of industries, proving essential for tasks requiring detailed workmanship and speed. In Perth, fabricators and artists frequently utilise this service for creating precise components, signage, and decorative elements.

Selecting the Right Materials for Laser Cutting

Selecting the appropriate material is a critical aspect of ensuring the success of any project employing laser cutting. A deep understanding of Quality Metal Sheets & Sizes will facilitate not only a smoother process but also guarantee the durability and aesthetic appeal of the final product.

Considerations for Material Choices

Various factors influence material selection, including the thickness, melting point, and reflectivity of the material. These elements affect how the laser beam interacts with the substance, thus dictating the quality of finish and accuracy of the cut.

Popular Materials for Laser Cutting

Metals are commonly selected for laser cutting, with steel, aluminium, and brass being favourites due to their excellent cutting characteristics. However, non-metal options like acrylic, wood, and textiles also offer diverse possibilities for designers and manufacturers.

Laser Cutting in Perth: Where Precision and Local Expertise Meet

To achieve the best results in laser cutting in Perth, partnering with a provider that understands local needs and is equipped with state-of-the-art machinery is crucial. Expertise in handling various materials and sizes is what distinguishes leading service providers in the region.

The Role of Local Experience and Equipment

Local experience has an unparalleled value, especially when it comes to material sourcing, understanding the regional market demands, and maintaining strict quality control. The availability of advanced laser cutting equipment additionally ensures the delivery of complex projects with high efficiency.

Custom Solutions for Perth’s Industries

Perth’s diverse industrial sectors demand custom solutions tailored to specific applications. Reliable service providers offer personalised advice to clients, thus ensuring that each project is a testament to innovation and precision crafted to the clients’ requirements.

The Future of Laser Cutting and Material Technology

The future of laser cutting holds promising advancements in speed, thickness capacity, and material variety. Ongoing research and development in the field are set to expand the boundaries of what can be achieved with this technology.

Innovation in Laser Cutting Technology

Innovation in laser technology is leading to more energy-efficient systems with greater control over laser parameters. This evolution paves the way for even more intricate detailing and the ability to cut through thicker and harder materials with minimal degradation in quality.

The Constant Evolution of Materials

Just as the technology evolves, so do the materials used in laser cutting. Advances in material science are producing metals and composites that are better suited for laser processing, offering improved results and opportunities for innovation in various fields of engineering.

Conclusion: Harnessing the Power of Laser Cutting in Perth

Laser cutting is an indispensable tool in the arsenal of modern engineering, providing a blend of speed, efficiency, and precision that is difficult to replicate through other means. For professionals in Perth, the journey to mastering this technology starts with choosing the right service provider, selecting the perfect material for your project, and staying abreast of technological developments.

Whether you seek detailed work for intricate designs or require substantial fabrication services, understanding and utilising the full capabilities of laser cutting will undoubtedly lead to superior outcomes. Innovate, create, and realise your engineering visions with the power of laser precision at your fingertips.

Are you ready to take on your next engineering challenge with laser cutting? Embrace the technology that is shaping the future of manufacturing and design, and let Perth’s local expertise be your guide to material mastery and project success.