CNC technology has undoubtedly revolutionized the manufacturing and design industries. Even if it’s been available for a while now, it has gained traction outside of commercial and industrial setups only in recent times.

For the first time since its invention, CNC machines have been made widely available to the manufacturing public, becoming more convenient to small to mid-sized businesses, professionals, and weekend do-it-yourself crafters.

That, for its part, has made people intrigued in using their CNC machinery and outsourcing CNC designs that might be cut out using industrial-grade machines outside of their facilities.

The allure of a computer doing hard work when designing complex parts is undoubtedly enticing. Still, before diving into the world of CNC, designers have to understand how to make the most of their machines.

In the following paragraphs, we will lay out some quick tips and useful guidelines that every CNC designer should follow to ensure that their design is optimized for CNC machining. With our four tips and some proper research, you will be able to make the most out of your CNC machines and automating milling processes to maximize efficiency and ease-of-use.

Know Your CNC Machine’s Limitations

CNC machining is a robust process; it’s versatile and flexible enough to tackle almost anything that you throw at it. However, like with any other manufacturing process, CNC machines do have their limitations.

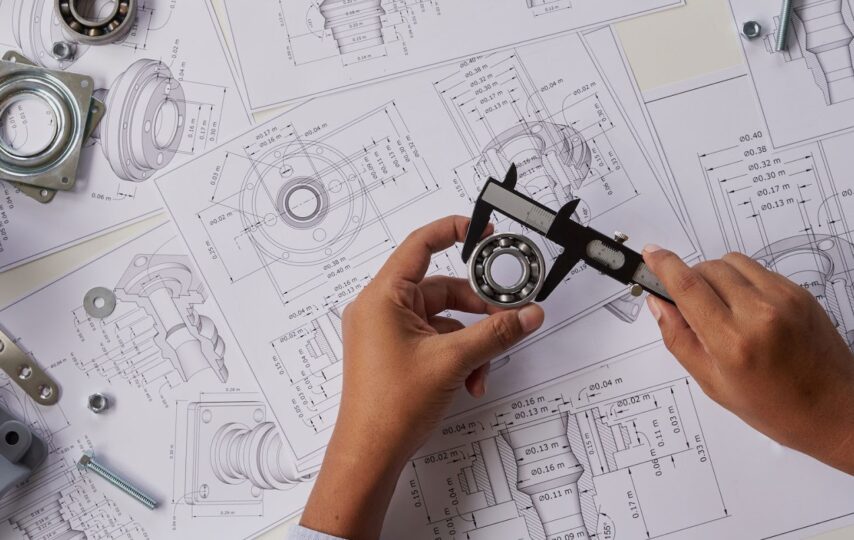

Photo from Industry Today

Additionally, most personal-use commercial-grade CNC machines don’t come with factory-grade capabilities and manufacturing options. That’s why every designer must understand what their machine can and can’t do to use it effectively.

As a CNC designer, first, you have to consider your CNC tool’s geometry and dimensions because most CNC machines come along with cylindrical drills with a pre-set cutting length.

While utilizing the CNC machine to conduct various CNC milling procedures, or mill out parts from the materials, never disregard the tool geometries’ effects on the finished product.

Anticipate that cut-out corners will have a radius that’s equal to or slightly larger than the radius of the machine’s drill bit, and don’t expect the machine to cut through any material thicker than its working cutting length.

Another significant limitation to consider is the operating range of your CNC mill. Most CNC machines can cut from right above the plane of your chosen workpiece, so you won’t be able to use the machine to cut out parts on a vastly different angle, for instance, from the side.

For that reason, it’s more tricky to machine out designs that are as wide as they are long. More higher-end CNC machines can mitigate this limitation, so if you want to achieve a more complex shape, you can always turn to the latest state-of-the-art 5-axis and 6-axis CNC machines.

Still, if you’re not ready to spend that kind of money, remember to always make sure that your design considers your chosen CNC machine’s limitations.

Keep Tolerances In Mind

CNC machine’s tolerances refer to the amount of error or variation acceptable when milling out parts from working materials. There are two main types of CNC tolerances: general tolerance and part tolerance.

General Tolerance

General tolerance refers to the total product tolerance for the designed parts in their entirety. Usually, this tolerance is plus or minus five-thousandths of an inch for metals and a hundredth of an inch for plastics.

If you’re working with an outsourcing company to produce your CNC machined parts, know that those different CNC manufacturers offer varying levels of general tolerances that they apply when clients fail to specify their required general tolerance upfront.

Part Tolerance

The second type of tolerances refers to any design element that needs to be more precise and accurate than most of the other parts of the CNC design. More detailed designs usually mean more prep time and a more involved CNC milling process.

Because of that, part tolerances likely result in longer processing times and more expensive service fees if you use third-party collaborators.

In any case, while designing your CNC part, don’t forget to keep tolerances in mind when designing an end product that will require a high degree of precision and accuracy.

Photo from Pixabay

Design Each Part With The CNC Machine In Mind

When designing specific parts to be manufactured with CNC machines, it’s essential to not only look at the designs in their entirety but also to pay maximum attention to the individual parts that make up the design. Keeping your machine’s capabilities in mind will help you figure out which aspects of your design might be unachievable and demand design edits. Here’s what to pay attention to:

- Internal corners and edges. As we previously mentioned, make sure to grant ample allowance for any inner corners that might consider your drill bit’s diameter.

- Wall thickness. When designing your product, always ensure that the walls are thick enough, so there aren’t any significant vibrations during the milling process.

- Holes and cavities. Set the radius of any pockets in your product to be at least four times the diameter of your machine’s cutting tool to avoid going beyond the machine’s advisable cutting length.

Strongly Consider The Materials

Selecting a material to work with is a crucial factor in optimizing your final CNC design. It’s best to always consider material characteristics like weight, rigidity, chemical and thermal resistance, density, ease-of-use, cost, and more.

All in all, you’ll be working with one of the three types of materials that are suitable for CNC machining: plastics, metal, and wood.

Plastics are more cost-effective than metals and wood. Still, they don’t offer the rigidity, weight, and structural integrity that metals do, so they are most useful for parts and products that don’t encounter too much stress or extreme wear and tear.

More or less, metals are the industry’s standard for factory-grade industrially CNC-machined parts and products. Softer metals like aluminum are favored, but if metals with denser and heavier characteristics are required for a specific project, steel is the usual material of choice.

Wood is exclusively used for the production of furniture and finishing fixtures. Out of the three materials suitable for CNC machining, wood is the most cost-effective and most comfortable material to work with, but has its niche in the construction and furniture industries only.

Photo from Pinterest

In Conclusion

It’s a great thing to know all the different particulars about the CNC machining process so that you can plan your designs accordingly. However, it’s essential to know your CNC machine or the third-party company that you’re planning to outsource to, the tolerances of the final product when compared to its intended use, and the material you’re planning to use.

Even if it might seem a little bit intimidating, know that designing your CNC machined products is a whole process, and you have to know your part of the task. Keep our four tips in mind, and good luck with your next CNC designs.