Regularly checking and maintaining your machines or your engine is essential for long-term use. When you are dealing with broken or worn parts that cause your machine to no longer function optimally, you will, of course, have to replace them. This is usually possible by buying spare parts, but in some instances you cannot do this unfortunately. Sometimes the parts are no longer produced, for example. Thankfully this does not mean that you have to buy an entire new machine or engine. Instead, you could ask a CNC machining service to make a replacement part. This can also be done by a 3D print service, as 3D printing can overhaul your machine or engine in a simple and efficient way.

Engine overhaul

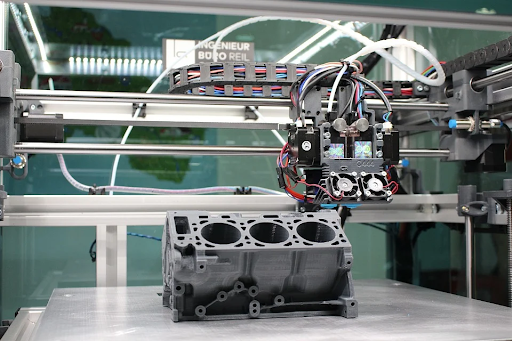

A 3D printer can be useful for an engine overhaul. During an engine overhaul, the engine of a car for example is completely cleaned and stripped of oils and greases. Subsequently, all parts are checked and an analysis of the cause of problems that are encountered follows. If necessary, necessary parts are disassembled. Is the part broken and can you not get a new one? In this case, a 3D printer can be the solution, as mentioned before. The 3D printer prints the part through a detailed design. Replace the broken part and the engine is like new again.

Machine overhaul

If your machine needs a makeover or if a part is broken a machine overhaul must definitely be carried out. Many companies postpone this as long as possible, because a machine cannot be used during an overhaul. This causes a standstill. But if a company does not maintain its machines, it will eventually break down and you will have even more problems. Does a part appear to be broken? Then a 3D printer can be a solution. First a 3D drawing has to be made of the part. Convert this to a digital file so that the 3D printer can read it. Subsequently, the machine can print the broken part by printing layers of filaments on top of each other. Once this has been finished, you have to replace the broken part with the 3D printed one. By doing this, your machine will last a long time again, just like the revised engine.

Maintenance of 3D printing machines

It is wise to have the machines that your company depends on overhauled once in a while to enjoy them for as long as possible. The standstill of a machine often results in a lot of money lost. Constructors and machine builders regularly know that 3D printing can be used for the production of a specific part, such as a gear wheel, sealing cap or connecting piece. Because each part is drawn and produced to fit precisely in the engine or machine, you can be sure that the 3D printed part will fit and that your engine or machine will run again as quickly as possible, while you can use it for a long time as well because of the new part.