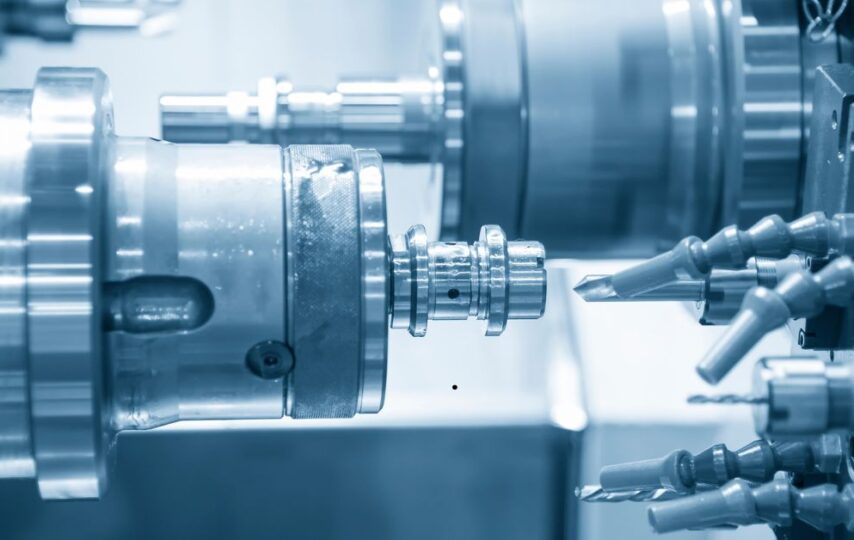

CNC cutting shapes aluminum into precise parts. CNC machines precisely cut, drill, and grind metal using digital design files. Quality and reliability-focused organizations like this method because it creates complicated geometries and perfect precision.

Aluminum CNC Machining in Practice

Many industries employ CNC machining for aluminum manufacture, including:

- Aerospace manufacturing includes brackets, housing, and engine parts.

- We make engine blocks, gearbox boxes, and custom car parts.

- Heat sinks, enclosures, and connectors are made in electronics.

- The medical industry makes devices for surgery, implants, and instruments for diagnosis.

- Designing molds, prototypes, and custom components for common things is consumer goods.

- Industrial equipment makes gears, housings, and other parts.

CNC Machining Service Selection: What to Look for

Consider these factors when choosing an automated machining service for aluminum components:

Experience and expertise: Look for a successful service provider in your industry.

Advanced Equipment: Ensure the service uses cutting-edge CNC equipment and tools.

Available Materials: Choose a service with many aluminum alloys.Make sure the provider has solid quality control. This matters in quality assurance.

Customer Support: Pick a company with great customer service.

Turnaround Time: Choose an aid provider who can offer high-quality results on time.

Understanding Aluminum CNC Machining Services’ Importance

Companies that demand quality, efficiency, and versatility need aluminum CNC machining service. Explaining why:

With bespoke machining, you can ensure that each component meets your specific needs.

You can differentiate your items from competition by using high-quality, precision-engineered equipment throughout manufacture.

More efficient processes and less material waste reduce production costs.

Cutting-edge CNC technology and skilled engineers ensure fast turnaround.

Aluminum CNC Machining Prospects

Technology and industry needs will shape aluminum CNC machining’s future:

- Robots for carrying, removing, and inspection are becoming more widespread in automation and robotics.

- Optimizing machining processes with AI and ML to increase speed and precision.

- Addition and subtraction occur. Hybrid manufacturing uses CNC machining and 3D printing.

- Development of green machining technologies and materials promotes sustainability.

- Modern production relies on CNC machine service for aluminum due to their precision, efficiency, and variety. Working with a reliable CNC turning service can help you prototype or increase production.

- Aluminum machining services using CNC machines help companies stay competitive and meet market demands with high-quality goods. Cutting-edge technology and great craftsmanship enable these services.

- If you need reliable and competent aluminum CNC machining service, explore your options now. This improves production efficiency.