The vast and complex world of Powerstroke engines requires that the specific functions of each component be clearly understood to attain optimal results. One of these critical elements is the CCV system. As enthusiasts and experts, this comprehensive guide seeks to demystify the operation of the CCV in Powerstroke engines by giving readers a deeper understanding of its role.

Unveiling the Purpose of CCV

Engine Breathing and Emissions Control

The CCV in Powerstroke engines serves a dual purpose: controlling the engine’s breathing and managing emissions. It is an advanced setup intended to keep the engine in good condition and meet strict emission regulations.

Managing Internal Pressure

The main objective of the CCV is to control internal compression within an engine. During engine operation, gases and pressure accumulate in the crankcase. The CCV helps release these gases and avoids pressure problems that would otherwise affect engine performance.

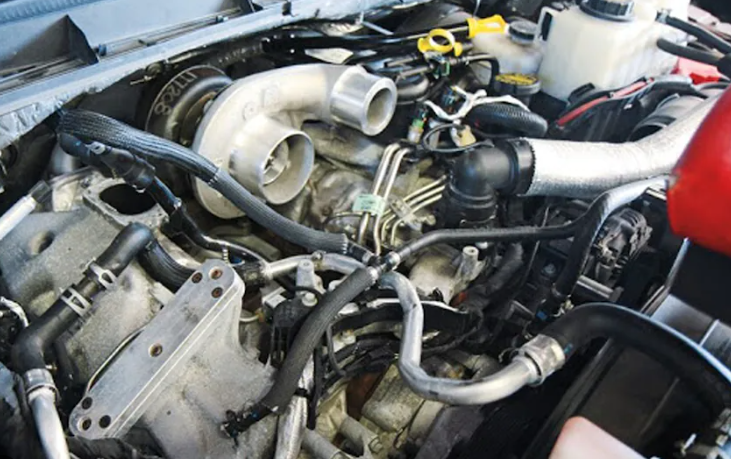

The Mechanics of CCV Operation

Filtering Out Contaminants

Within the CCV system is an embedded filtration mechanism. This element ensures that only gases get into the atmosphere while contaminants such as oil and moisture are captured back to be burnt in the engine. This process improves combustion performance and reduces pollution.

Positive Crankcase Ventilation (PCV) Valve

The center of the CCV system is a PCV valve. This valve controls gas flow to ensure a proportional outlet and avoid unnecessary discharges. The PCV valve is an important part that needs to be checked and maintained frequently.

Impact on Engine Performance

Prevention of Pressure-Related Issues

A significant contribution of the CCV in dealing with internal pressure is essential to prevent possible problems like oil leaks, gasket failures, and seal damage. This, in turn, helps protect the Powerstroke engine’s overall efficacy and life.

Reduction of Environmental Footprint

Apart from the issue of engine health, CCV contributes to decreasing the environmental impact of Powerstroke engines. The redirecting and filtering emissions help meet stringent emission standards and improve air quality.

Maintenance and Troubleshooting

Regular Inspection and Replacement

If required, regular inspection and replacement of the parts, such as the PCV valve and filters, ensure that the CCV System remains effective after a long time. Please address these elements to ensure good engine performance and higher pollution levels.

Troubleshooting Common CCV Issues

The knowledge of most typical CCV troubles, for instance, clog leakage or valve failure, is essential for timely solving. Prompt detection and resolution of problems lead to undisrupted engine operation, eliminating expensive repairs.

Upgrading the CCV System

Performance Enhancements

For fans dedicated to increasing their Powerstroke engine’s performance, looking into alternative CCV system enhancements is a viable option. Typically, CCV kits that provide high-performance filtration enhance ventilation and improve engine function.

Exploring the World of Upgrades EGR Delete and 6.7 Powerstroke CCV Reroute Kit

To improve engine performance, enthusiasts consider modifications such as the EGR delete and 6.7 Powerstroke CCV reroute kit. When performed responsibly and according to regulations, these improvements can take your Powerstroke engine’s performance even further toward an optimum level.

Conclusion: Navigating the CCV Landscape

Therefore, deciphering the contribution of CCV to Powerstroke engines shows its essential responsibilities in maintaining internal pressure balance, minimizing unwanted exhaust emissions, and sparing engine life. Knowing the details of the CCV system gives Powerstroke lovers the confidence to navigate their engine landscape.

Read More