In recent years, the printing industry has experienced a significant transformation thanks to advancements in digital printing technology. Among these innovations, the A3 DTF (Direct to Film) printer and the UV flatbed printer stand out for their versatility and efficiency, making them ideal for small businesses and home studios. This article will explore how these two technologies are revolutionizing the world of custom printing, particularly in the context of starting a printing business or a T-shirt business.

A3 DTF Printer: Revolutionizing Fabric Printing

The A3 DTF printer is a game-changer in the fabric printing industry. DTF printing involves printing a design onto a special film, which is then transferred onto fabric using heat and pressure. This technology is particularly suited for small businesses or individuals looking to start a T-shirt printing business. The A3 size of the printer makes it compact enough for a home studio yet capable of producing high-quality prints.

One of the key advantages of the A3 DTF printer is its versatility. It can print on a variety of fabrics, including cotton, polyester, and blends, without the need for pre-treatment. This makes it easier and more cost-effective for small businesses to produce custom T-shirts, hoodies, and other apparel.

Procolored is a well-known brand in the printing industry, offering a variety of printers like A3 DTF printers, which are highly regarded for their industrial-grade print quality and speed, suitable for fabric printing. They also provide UV flatbed printers, capable of printing on diverse materials like plastic, metal, and glass, ideal for custom printing projects.

UV Flatbed Printer: Expanding the Horizons

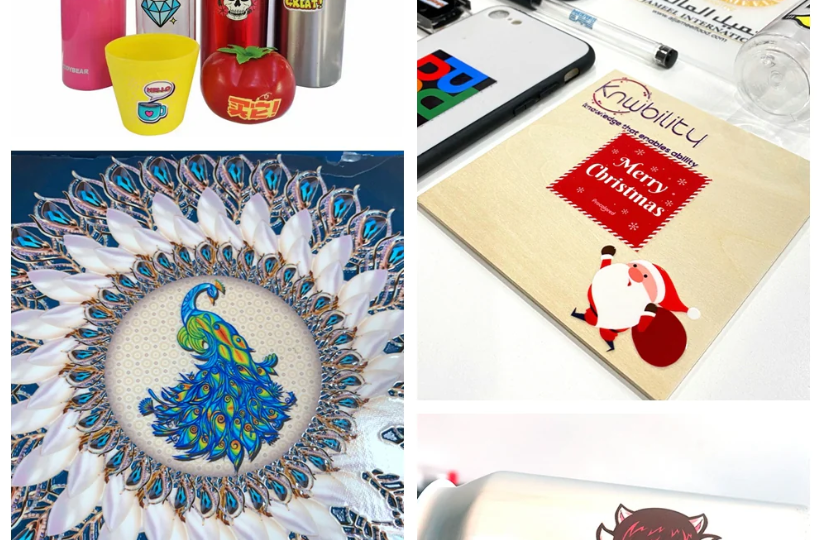

The UV flatbed printer, on the other hand, is known for its ability to print on a wide range of surfaces. This includes not only fabrics but also materials like plastic, glass, and metal. The UV printing process uses ultraviolet light to dry or cure ink as it is printed. This results in highly durable, weather-resistant prints, perfect for outdoor signage, custom gifts, and personalized items.

For those considering how to start a print-on-demand business or a custom printing service, the UV flatbed printer offers unparalleled flexibility. You can create custom phone cases, personalized gifts, and unique home decor items, all with the same machine. This versatility opens up numerous avenues for creativity and entrepreneurship.

Starting a Printing Business with the Right Tools

For entrepreneurs wondering how to make DTF transfers at home or start a T-shirt printing business, the A3 DTF printer and UV flatbed printer present lucrative opportunities. Here are some steps to get started:

1. Market Research: Understand your target market and the kind of products they are interested in. This could range from custom apparel to personalized home decor.

When choosing the right equipment for your printing business, consider the following factors:

– Print Quality and Speed: Evaluate the resolution and speed of printers. Higher resolution printers produce finer details, crucial for high-quality prints. Speed is key for meeting customer demands and scaling up production.

– Material Compatibility: Different printers handle different materials. For instance, some are better suited for textiles, while others excel at rigid materials like glass or metal.

– Size and Scalability: Consider the physical size of the printer and its printing capacity. A larger printer might offer more versatility but requires more space and investment.

– Maintenance and Durability: Understand the maintenance requirements. Reliable printers with durable parts reduce downtime and maintenance costs.

– Budget and ROI: Balance your budget with the printer’s capabilities. A more expensive printer might offer better quality and speed, providing a better return on investment in the long run.

Learning the Craft

– Training and Skill Development: Invest time in learning the technical aspects of printing. Online courses, tutorials, and workshops can be valuable.

– Software Proficiency: Be proficient in design software like Adobe Photoshop or Illustrator. This is crucial for creating or modifying designs.

– Networking with Other Professionals: Joining forums, attending trade shows, and connecting with other printing professionals can provide valuable insights and tips.

Marketing Your Business

– Online Presence: Build a strong online presence through a website and social media. Showcasing your work and engaging with your audience can attract customers.

– Local Market Engagement: Participate in local events, fairs, and markets. This can help build a local customer base and brand recognition.

– Customer Service: Excellent customer service and building relationships with clients can lead to repeat business and referrals.

Quality and Innovation

– Continuous Improvement: Stay updated with the latest trends and technologies in printing. Adapting to new methods can keep your business competitive.

– Feedback and Adaptation: Listen to customer feedback and adapt your products and services accordingly. This helps in meeting market demands and improving quality.

– Eco-Friendly Practices: Consider adopting eco-friendly printing practices. This not only helps the environment but can also be a selling point for environmentally conscious customers.

By considering these additional points, you can build a more comprehensive understanding of what it takes to start and run a successful printing business. Whether it’s choosing the right equipment, like Procolored printers, mastering the craft, marketing effectively, or focusing on quality and innovation, each aspect plays a crucial role in the success of your venture.

Conclusion

The advent of A3 DTF printers and UV flatbed printers has made it more accessible than ever to start a custom printing business from a home studio. With their versatility, ease of use, and the growing demand for personalized products, these technologies offer a promising path for entrepreneurs in the digital printing industry. Whether it’s fabric or a wider range of materials, these printers ensure that your creative vision can be vividly and effectively brought to life.

Q&A:

Q1: What is the advantage of using an A3 DTF printer for a T-shirt printing business?

A1: The A3 DTF printer is excellent for T-shirt printing due to its ability to print on various fabric types without pre-treatment. Its compact size makes it suitable for small businesses and home studios, and it offers high-quality prints with versatility in design options.

Q2: How do UV flatbed printers differ from traditional printing methods?

A2: UV flatbed printers use ultraviolet light to cure ink instantly as it’s printed. This method allows for printing on a wide range of materials like wood, metal, glass, and more, not just fabric. The prints are durable, high-quality, and weather-resistant, making them ideal for outdoor signage and custom gifts.

Q3: Are Procolored printers suitable for beginners in the printing business?

A3: Yes, Procolored printers are designed with user-friendliness in mind. They offer a range of printers that are suitable for both beginners and experienced users. The company also provides tutorials and support, making it easier for newcomers to learn the printing process.

Q4: What should I consider when choosing between different Procolored printers?

A4: Consider the type of products you want to create, the range of materials you plan to print on, and the size of your workspace. Procolored offers a variety of printers, including A3 and A4 DTF printers, UV flatbed printers, and more, each catering to different needs.

Q5: Can Procolored printers be used for a print-on-demand business?

A5: Absolutely. Procolored’s range of printers, especially their UV flatbed and DTF printers, are well-suited for print-on-demand services. They offer flexibility in printing on different materials and can handle custom orders efficiently, which is key in a print-on-demand business model.