Factors, for example, plan necessities, cost, and possibility to fabricate direct which casting process is generally appropriate to make an item. This article depicting investment casting is proposed to help you settle on an educated casting choice.

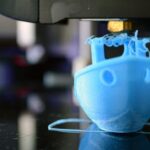

Investment Casting (Lost Wax Casting)

Investment DAWANG CASTING produces exact segments while limiting material waste, energy, and ensuing machining. It can likewise guarantee the creation of perplexing parts. This makes the investment casting process very helpful to configuration engineers.

Investment Casting Example

The objective is to comprehend what is implied by investment casting. All in all, What precisely is the investment in “investment” casting? The expression “contributed” truly conveys the significance of “dressed” or “encompassed.” Investment casting utilizes a shell made of ceramic, mortar, or plastic that is conformed to a wax design. The wax design is softened and taken out in a heater and metal is filled the shell to make the casting.

What is investment casting utilized for? How about we separate the investment casting creation process for a more prominent agreement:

A. Making The Pattern

It uses an example with similar subtleties as the completed part, then again, actually there is a remittance for warm compression (for example contracting).

Examples are ordinarily made of wax utilizing a metal infusion pass on.

B. Mounting The Wax Patterns And Creating The Tree

When a wax design is created, it is collected with other wax segments to shape the entryway and sprinter metal conveyance framework. Contingent upon the size and design of the ideal completion segment, various wax examples might be processed utilizing a solitary tree.

C. Making The Mold Shell

The whole wax design gathering is plunged in an artistic slurry, covered with sand plaster, and permitted to dry.

Patterns of wet plunging and resulting stuccoing are rehashed until a shell of the ideal thickness is made. That thickness is incompletely directed side-effect size and setup.

When the artistic shell has dried, it turns out to be adequately solid to hold the liquid metal during casting.

D. Wax Removal

The whole gathering is put in a steam autoclave to soften away a large portion of the wax.

Any excess wax doused into the ceramic shell is worn out in a heater. Now, the leftover wax design and gating material have been totally taken out and the earthenware form stays with a hole looking like the ideal cast part.

This high-temperature activity likewise expands the strength and dependability of the earthenware material. Also, it assists with limiting the response of the shell and metal during pouring.

E. Liquefy And Cast

The shape is preheated to a particular temperature and loaded up with liquid metal, making the metal casting.

Almost any amalgam can be delivered utilizing this process. Either air dissolving or vacuum liquefying might be utilized as directed by the compound science. Vacuum liquefying is used primarily when responsive components are available in the composite.

F. Last Operations

When the casting has cooled adequately, the form shell is split away from the casting in a knockout activity.

The doors and sprinters are cut from the casting, and if fundamental, last post-processing sandblasting, granulating, and machining is performed to complete the casting dimensionally.

Non-ruinous testing may incorporate fluorescent penetrant, attractive molecule, radiographic, or different assessments. Last dimensional investigations, composite test outcomes, and NDT are checked before shipment.

Benefits Of Investment Casting Process

Size Range:

Albeit most investment castings are little, the investment process can deliver castings gauging in excess of 1,000 pounds. This ability is restricted to a moderately modest number of investment casters and requires uncommon aptitude in taking care of.

Adaptable And Intricate Shapes:

Investment casting gives steady and dreary close resistances alongside complicated entries and shapes. A large number of these arrangements are difficult to deliver. For instance, where machine devices can’t reach. Accomplishing net-shape or close net-shape cast segments can significantly decrease post-cast processing costs.

Investment casting is a decent option in contrast to weldments or creating. A large number can be joined into a solitary casting. The more that are consolidated, the better the assembling proficiency. Changing over multi-piece segments to a solitary investment casting commonly conveys more dimensional precision and decreased part intricacy.

Read more about: HISPEED LASER

Precise And Smooth Surfaces:

The fired shell utilized is worked around smooth examples created by infusing wax into a cleaned aluminum pass on. A 125 miniature completion is standard, and surprisingly better completes are normal.

Investment castings contain no splitting line in light of the fact that just one shape is utilized as opposed to two half forms, (for example, on account of sand casting). Guidelines for surface imperfections and beautifiers are talked about and settled upon with the client dependent on the capacity.

Dimensional Accuracy:

Commonly, “standard” investment resiliences are +/ – 0.010″ for the primary inch and +/ – 0.004″ for each succeeding inch.

The plan stage can bring about a drawing that decreases or even dispenses with past machining necessities to deliver a similar part.

The expense of any part increments in relation to the accuracy of its dimensional necessities. Regardless of whether if it’s castings machined parts or manufactures. A nearby plan survey will allow adjustment to resistances, undermines, daze openings, and so on to permit higher creation yields and lower piece costs. On the off chance that nearer than cast resiliences are needed, the machining needed for investment casting will be not exactly traditional castings or created parts.

Quality And Integrity:

Casting trustworthiness is a significant element of the process. Investment casting has a long history of serving requesting areas, for example, gas turbine motor, petrol, substance, protection, and clinical.

Contemplations When Using Investment Casting

Tooling Cost:

For low amount necessities, it very well might be more costly than different techniques if lasting tooling is sought after. For those applications, SLA or printed examples might be a practical other option (in any event, for an amount of one).

Introductory expenses are another key factor while deciding if investment casting brings the best worth. The investment cast instrument normally comprises of different parts fitted together to create the mind boggling segments. This “front end” cost isn’t irrelevant yet can be effortlessly balanced by the absence of ensuing machining or potentially creation.

Size Limitations:

It’s feasible to make investment castings in a scope of sizes. There is a maximum cutoff on that range, which is not exactly other formed innovations like sand casting.

Little Structures:

Investment casting is an astounding decision for flimsy walled applications, however little interior shapes that utilization centers can introduce difficulties. Openings ordinarily can’t be more modest than 1/16″ (1.6mm) or more profound than 1.5 occasions in width.

Timing:

The multi-step investment casting process is additional tedious than different processes. The processing time can be more limited than different other options.

Conclusion:

Similarly as with most materials and plan choices, a conversation with a metals master can help drive the best choice. To get familiar with this process or to decide whether it is a fit for your application, if it’s not too much trouble, reach us.