Pumps play a vital role in a variety of applications. This mechanical device ensures the proper fluid flow required for different processes. Different types of pumps are used to deliver different fluids from one place to other. Pumps are an important device for all industries. The common types of pumps used across industries include gear pumps, reciprocating pumps, piston pumps, and centrifugal pumps.

Different pumps have different pros and cons; however, the piston pump is the most commonly used.

What is a Piston Pump?

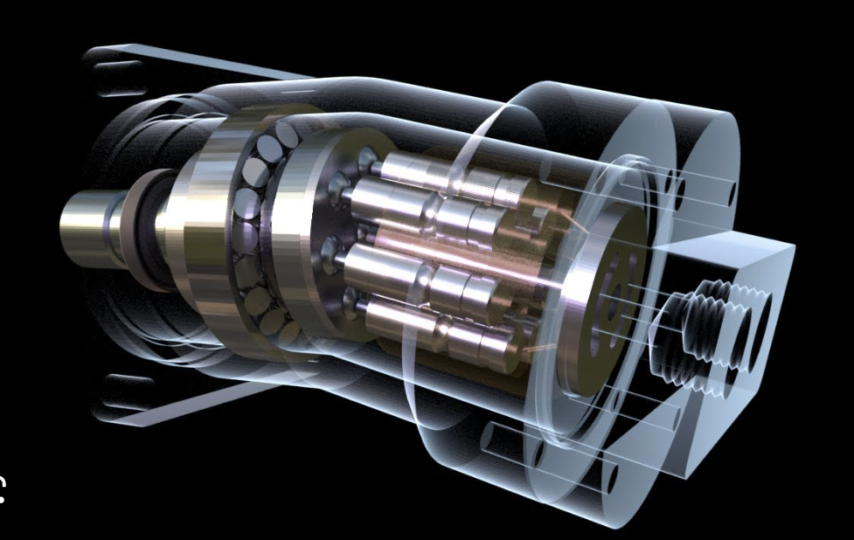

A piston pump is a versatile device used for a variety of applications. This positive displacement pump works to flow liquids or compressed gases from one point to another. It consists of a piston, a chamber, and two valves. These have a high-pressure seal that reciprocates with the piston. As a type of hydraulic pump, it ensures efficient performance where consistent high pressure is needed such as in an irrigation system. A piston or plunger pump works by driving the piston down into the chamber, resulting in compressing the liquid. The inlet valve opens and the outlet valve closes when the piston is drawn back up. The suction is created that helps in drawing in new media for compression.

A typical piston pump consists of a wheel or revolving shaft for operating the piston. This rotary pump has revolving components that twist and use the power from power sources. There are different types of piston pumps such as lift pumps, force pumps, axial pumps, and radial piston-pump. Of all these types of pumps, lift and force pumps can operate manually. A piston pump moves fluid through a cylinder-shaped chamber by using the reciprocating motion of a piston rod. Pressure builds up as the piston moves through the cylinder, forcing the fluid through the pump. The fluid flowing through the pump pulsates as the piston moves through the cylinder.

Benefits of Piston Pumps

A piston pump has many benefits as compared to other pumps. Its high suction performance and exceptional delivery rate immensely help in working with highly viscous materials. As a tough and resilient pump, it is particularly helpful in dealing with heavy fluids. Piston pumps have a wide pressure range that can be controlled without affecting the flow rate. They have also a constant discharge rate; however, pressure change and discharge rate have little effect on performance. The key benefits of piston pump include:

- Wide pressure range

- Manageable force without moving the flow rate

- Pressure changes and flow rate changes have minimal impact on the outcome.

- Good control device design enables the moving of thick fluids and slurries.

Piston and plunger pumps are primarily used to handle very low flow rates at very high pressure. These pumps have the self-priming capability and high efficiency. These are comparatively expensive but one of the most efficient types of pumps. However, the design of the piston pump is vulnerable to contaminants. With an excellent pressure rating, piston pumps are a great solution for many high-pressure hydraulic oil pumping applications.