When it comes to transmitting power, Medium Voltage (MV) cables play a role. This article dives into the composition design features and various applications of MV cables, across industries. Additionally it investigates their contribution to the energy sector while also discussing important safety precautions and maintenance practices.

Having an understanding of these aspects can optimize the utilization of MV cables ensuring secure power supply in diverse applications.

Understanding Medium Voltage Cables

To delve into the realm of medium voltage cable it’s essential to grasp their design, operation and key characteristics within installations.

The choice of materials and design aims at minimizing damage over time for a lifespan.

However installation challenges often arise due to procedures involved. These challenges include the requirement for jointing techniques precise laying guidelines and strict safety measures.

Consequently engineers and installers must possess an understanding of these cables unique characteristics along, with anticipating obstacles encountered during installation.

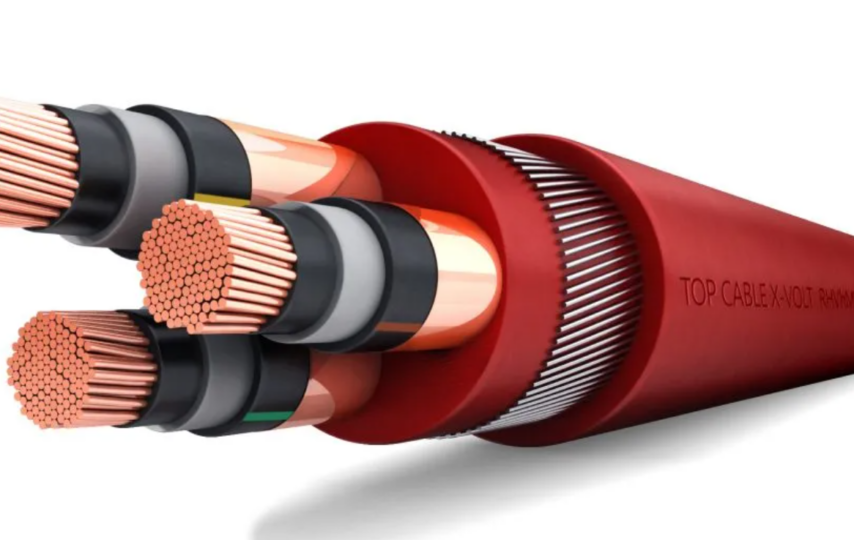

Construction and Design Features

When it comes to constructing and designing medium voltage cables there are elements that are incorporated to ensure optimal performance, longevity and safety in various applications. One crucial element is the use of Cable Insulation Materials. These materials provide both electrical resistance effectively separating parts and preventing leakage currents or short circuits. Commonly used materials, like linked polyethylene (XLPE) or ethylene propylene rubber (EPR) are chosen for their high dielectric strength and excellent thermal properties.

Another essential aspect of the design is the implementation of Voltage Regulation Techniques. These techniques, such as tap changing and voltage stabilizers help maintain a voltage level ensuring that the cable operates effectively under varying load conditions.

The combination of these features contributes significantly to the durability and dependability of medium voltage cables.

Key Applications in Industries

Medium voltage cables play a role in delivering power supply across various industries. They are extensively used in sectors like oil and gas mining, manufacturing industries due to their ability to power machinery efficiently while enabling operations.

In terms of infrastructure development medium voltage cables are indispensable, for urbanization projectsThey make sure that public utilities, transportation systems and businesses have a source of power. The cables are designed to be strong. Can withstand conditions, which makes them ideal, for outdoor and underground installations. As a result they play a role, in the construction and upkeep of infrastructure.

Role, in the Renewable Energy Sector

Medium voltage cables play a role in bridging the gap between power sectors and the emerging trends in green energy. They are essential for addressing challenges related to integrating energy sources into the grid. By transmitting electricity from renewables these cables help minimize energy loss during long distance transmission allowing for utilization of green energy.

Grid stability, a concern when it comes to incorporating energy can be improved with the use of medium voltage cables. These cables are designed with insulation and protective sheathing to handle the power supply that is characteristic of renewable sources. By ensuring a power supply they contribute to enhancing grid stability.

Therefore medium voltage cables play a role in promoting growth and sustainability within the energy sector.

Safety Measures and Maintenance

To ensure functionality and longevity of medium voltage cables it is crucial to implement safety measures and diligent maintenance practices. This involves having an understanding of the cables design, material properties and operating conditions.

Preventive practices include inspections to identify signs of wear and tear monitoring temperature and load conditions well as ensuring proper installation procedures. By implementing these measures we can minimize the risk of cable failure while optimizing system reliability and efficiency.

Additionally maintaining a safety protocol is essential, for mitigating accidents.

Employees are trained in handling techniques emergency response protocols and the proper use of protective equipment. Consistent maintenance along, with a safety mindset guarantees the effective and dependable functioning of medium voltage cables.

FAQs

1. What are the cost implications of using medium voltage cables compared to voltage ones?

Medium voltage cables may have costs but they offer better voltage efficiency and longer cable lifespan. Over time these advantages can offset the expenses making them an economical choice compared to low voltage alternatives.

2. How does the installation process of medium voltage cables differ from high voltage cables?

When it comes to installing medium voltage cables it is important to handle the cable insulation with care and prioritize safety during installation. This process is less complex, than installing voltage cables, which require equipment and specialized expertise for safe installation.

3. Are there any concerns associated with the use of medium voltage cables?

Yes there are concerns related to medium voltage cables. These include challenges in recycling due to their composition and potential emissions during production and disposal that could contribute to pollution and climate change.

4. What are some advanced technologies or innovations being developed in the field of medium voltage cables?

Innovations in the realm of medium voltage cables focus on advancements in voltage stability and improvements in cable insulation. These developments aim to enhance grid reliability improve power quality and minimize power losses ultimately optimizing energy efficiency.

5. What role does governmental regulation play, in the manufacturing and use of medium voltage cables?

Government regulations have an impact, on the production and application of medium voltage cables. Their main objective is to enforce safety standards ensuring that these crucial components, in our power infrastructure are reliable perform well and are safe to use.