The manufacturing sector has gone through massive advancements during the years. The manufacturing industry now extends further than past assembly line procedures using basic machines. Factories in present times function with smart technology which upgrades production speed while decreasing errors and maximizing resource utilization. The camera module functions as an essential tool which propels this change in manufacturing. Due to their compact yet strong design camera modules enable business establishments to track their manufacturing processes along with product examinations and quality improvement activities. Modern manufacturing vitally depends on camera modules because they enable defect detection while maintaining operational efficiency and minimizing waste. Manufacturing facilities require these cameras to become more essential as they expand their adoption of intelligent technology. Supertek Module Company from China, a reliable high-end camera modules manufacturer which enables industrial businesses to fulfill current industrial requirements.

What Are Camera Modules?

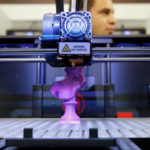

Camera modules operate as small electronic cameras which handle instant image capture and processing functions. The camera module consists of three main components that perform tasks to achieve high-quality image capture as well as video recording. The camera marketplace extends from elementary fixed-focus systems to developed AI-based vision systems.

Camera modules serve various industries because they can adapt in a wide range of applications. The manufacturing industry uses camera modules to oversee production processes and evaluate products while performing automated functions. Camera modules provide essential functionality to robots in addition to their use in healthcare equipment and security systems and automotive applications. The camera module manufacturer’s business partners can identify suitable solutions through their requirements which can include precise inspection together with automation capabilities and monitoring demands.

Making Production Faster and Smoother

Factory production efficiency stands as an essential priority in manufacturing while camera modules serve as components that boost assembly line operation speed and precision levels. Businesses can both monitor assembly line operations live alongside automatic detection of developing problems by adding these cameras to their production systems. The adoption of camera modules permits manufacturers to decrease operational slowdowns along with eliminating expensive system interruptions.

Camera modules provide their most important benefit through their capability to monitor operations in real time. These cameras operate automatically to examine the production line actively detecting errors that include equipment issues and component misalignments together with defects on the spot. Through this preventative method companies minimize the potential growth of small issues into problematic manufacturing delays.

Another major advantage is automation. Camera modules enhance operation speed through robotic and artificial intelligence systems which perform accurate work processes. Robotics arms receive their instructions from these modules as they perform product defect detection before packaging and inspect electronic component positions. Businesses employ camera modules to boost efficiency standards despite maintaining high quality levels. Supertek Module develops sophisticated camera modules which operate effortlessly with automated control platforms.

Better Quality Control with Smart Cameras

Manufacturers need high product quality in their manufacturing activities which camera modules have improved through advanced quality control procedures. High-precision imaging systems function throughout manufacturing to detect product defects that people typically miss. Production quality standards receive constant support from camera modules through their ability to identify flaws and measure dimensions and verify component alignment.

Speed is another key advantage. High accuracy and speed define camera modules since they examine thousands of products an hour better than human manual inspections can manage. The deployment of camera modules eliminates waste while maintaining customer safety by stopping defective products from delivering to end-users thus avoiding product recalls.

This advanced quality control system provides benefits to different industrial sectors. Operation inspection at automotive manufacturing facilities utilizes camera modules to check engine components along with circuit boards thereby avoiding system breakdowns. The placement of tiny chips on PCBs is verified by these systems in electronics manufacturing to ensure proper functionality. The food and beverage processing sector utilizes these cameras to verify both product packaging quality and correctness of labels. Camera modules enable businesses to achieve high-quality product delivery together with cost reductions in production expenses and waste reduction.

AI-Powered Vision: Smart Cameras That Learn

Camera modules show increasing intelligence through artificial intelligence systems (AI) implementation. AI-powered cameras build their understanding of images along with pattern identification to produce instant decisions which decrease the necessity for human oversight. Advanced manufacturing efficiency results from these systems while human mistakes become less frequent.

The main advantage of AI-driven camera modules relates to their ability to adapt defect detection. Traditional equipment-based inspection systems depend on static evaluation parameters but AI-driven cameras use library-sized data collections to advance their faulty detection capabilities throughout usage. The improved accuracy rate results from such methods because they decrease the number of false rejections. Artificial intelligence enabled vision systems through cameras discover subtle product flaws which standard camera systems would overlook in electronics production. The use of AI-powered cameras in logistics and warehousing helps track inventory movements and establishes better sorting optimization to improve efficiency.

CI-enabled cameras achieve process automation through automatic system adjustments. Automation systems become optimized by these cameras while their predictive capabilities anticipate maintenance requirements which allows factories to operate without interruptions. These intelligent vision systems will expand their role in production improvements through AI development to better serve industry needs.

Real-World Success Stories

Camera modules have brought significant positive changes to many businesses through their implementation in production systems. The automotive industry leader implemented high-speed camera modules as a real-time inspection system for engine components. The early detection of microscopic assembly flaws through these systems allowed the company to improve product quality through 30% lower defect rates and prevent expensive recalls.

A circuit board producer enhanced their manufacturing process through AI-powered camera modules which checked component placement accuracy as well as soldering quality. The inspection system raised productivity to 40% above normal speeds thus guaranteeing customer satisfaction with functional products.

Food and beverage companies have achieved advantages through their implementation of camera modules. The facility used automated vision systems to examine packaging facilities for both misaligned labeling and damaged packaging. The production accuracy bettered by 25% with simultaneous waste reduction occurring in the process.

Business operations achieve streamlined functions and enhance product quality alongside decrease of manufacturing mistakes through camera module implementations.

Challenges and Solutions for Using Camera Modules

Camera modules provide essential benefits but manufacturing businesses experience obstacles during integration into their manufacturing methodology. Businesses encounter three main problems with camera modules: expenses related to acquisition, compatibility issues with current technology infrastructure and the requirement of operators with sufficient expertise to utilize data output. Such barriers can successfully be addressed through proper implementation.

Businesses should launch initial small-scale tests before implementing camera modules on a large scale for a seamless transition process. The installation process becomes streamlined and system changes prove less necessary because of camera modules that utilize plug-and-play functionality. Working with a dependable camera module manufacturer provides businesses with both the right setup procedures and continuous operational support. Employee training that focuses on automated vision system operation promotes both system acceptance and delivers higher return from investments.

What’s Next for Camera Modules in Manufacturing?

Manufacturing industries will see innovative developments with camera modules during upcoming periods.

Technology improvements continue to advance camera modules systematically. Rapid industrial progress has led to the development of predictive defect detection through AI-powered camera technology which anticipates possible problems in advance. The manufacturing industry benefits from these technologies by allowing further minimization of waste as well as operational inefficiencies.

5G connectivity provides real-time data sharing functionality between manufacturing systems and camera modules. Profit centers will enhance their operational alignment through better system coordination while improving their ability to monitor quality control statistics. Future applications will incorporate augmented reality (AR) to assist inspection tasks and develop independent quality control stations that promise to reshape factory operations.

The continuing advancement of camera module technology gives businesses better capability to enhance their efficiency and quality standards while achieving competitiveness in modern automated environments. The partnership between businesses and Supertek Module enables them to obtain state-of-the-art camera solutions for advancing their position in contemporary manufacturing operations.