The use of PCBs in electronics is not only critical but is also the foundations of a lot of the gadgets we are using. Unlike that, from a smartphone to industrial machine, PCBs serve a crucial function to ensure smooth operations in all. The industrial manufacturing process still involves numerous steps needed for its PCBs to be built in a swift and accurate way. This is where NextPCB stands as a complete answer providing streamlined handiness for your board making needs by using the latest professional equipment with secured data transmission.

The people winning in the fast-changing environment of production of electronics require efficiency and quality, first of all. The really fast level of the technology development and new innovations makes that companies, as well as individuals, want their operations to be much well planned and as the result they seek assistance could get the best possible outcome.

Welcome to NextPCB, the numero uno name in electronic production of PCB & corresponding assembly services. Being a pioneer, NextPCB guarantees it best-quality products with high precision and with the full-satisfaction of our customers, the company has earned its name and a reputation as a leading industry player.

The following write-up unveils the crux of NextPCB service with all its *hardware* delectation and why it should be your first preference when procuring chips.

Understanding NextPCB:

NextPCB is US based vendor specializing in manufacturing and assembly of PCBs for electronic products in many industries and areas of application. By the attitude to quality, pricing and customers concerns areas NextPCB remained true to values and established it as a reputable partner in electronic PCB manufacturing for both companies and individuals equally.

Key Features and Services:

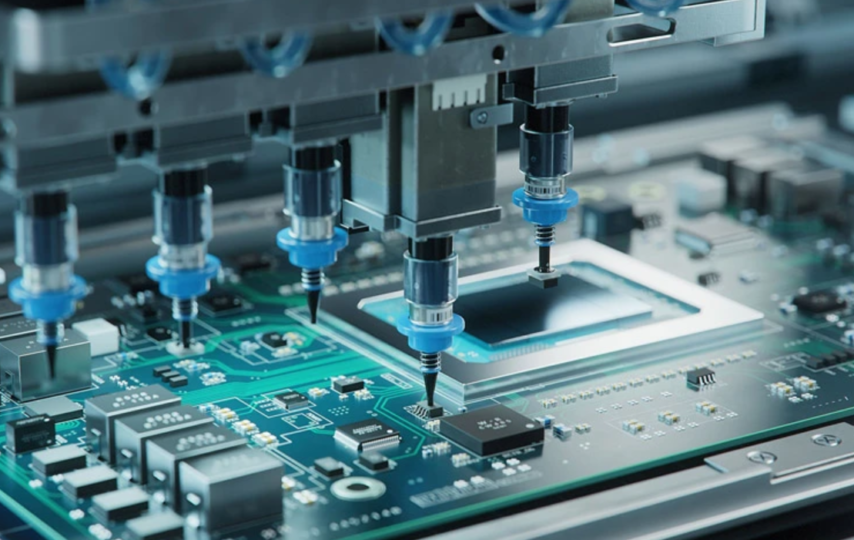

- Advanced Manufacturing Technology: NextPCB applies cutting-edge manufacturing process in order to ensure repeated perfection in any unique printed circuit board. From sloppy stage to the scale production, their advanced facilities are furnished with different kinds of tools intended for any specification.

- Quick Turnaround Times: In the speedy electronics industry, NextPCB knows all about the exactness of a fast turnaround time. It does not matter whether you need a prototype to be done in an emergency or a large number of samples to be done fast, NextPCB outputs tremendous results not only quickly, but in high quality.

- Customization Options: Beside, NextPCB has given a freedom to add any design/hardware which is according to your project’s requirment. There is no compromise in their choice of quality material and finishes, and the optimization of the layout of the spaces to allow clients’ creativity to translate into reality.

- Comprehensive Support: PCB manufacturing might appear challenging in many ways for those that are not familiar with the process. To assist customers through the whole process, that includes consulting on the design phase to delivery the final product, Next PCB offers full support to ensure desired results. Its specialized staff is readily on hand to respond to customers’ queries as well as to help them through a difficult time.

- Competitive Pricing: The cost effectiveness is a desire for all kinds of business, regardless the business size, and NextPCB proposes you a competitive pricing without sacrificing quality at all. Efficiency is the watchword which enables them to make both affordable and customized solutions offering excellent value for the unique needs you have.

Also read: How AI is Revolutionizing PCB Design

Why Choose NextPCB?

- Quality Assurance: The company stature of nextPCB is to have the strive for the steadfast quality in the whole process of manufacturing. All quality control measures of the product quality are implemented to assure that each PCB satisfies or even exceeds the accepted industry performance.

- Reliability and Consistency: When computing boards are concerned, reliability is a lifeblood. Due to its commitment to consistency and integrity, you can confidently trust NextPCB products, as they are sure to provide a reliable performance through various high demanding processes.

- Customer Satisfaction: Being customer-focused is ranked high on nextPCB. The team, with their experience and welcoming attitude, is ready to cater to both established professionals and those novices in the field. Whatever your level of in-depth knowledge, count on their support to help you gain a foothold in the realm of electronics.

Also read: What is a PCB or Printed Circuit Board?

Conclusion:

NextPCB provides the full package of PCB manufacturing services, that covers all special demands and requests of yours. The company has the technology and quick turnaround time tailored to their clientele, the customization options, competitive pricing, and unbeatable customer support that make it the partner for businesses and individuals that need to speed up their PCB production process.

From developing a new product crystal-clear prototype to large scale projects, NextPCB is capable of providing skilled and efficient services to give more than expected results. Buckle up and visit their website today to get more info and be on the way to achieving your dream of fabrication of your PCB designs.

Frequently Asked Questions (FAQs) about NextPCB:

- What does NextPCB provide clients service-wise?

- We are at the service of all our customers with full-range PCB manufacturing and assembly solutions. Prototype fabrication of any number of boards, mass production goals being reached with flexible assembly lines, modules being placed on the boards and components being supplied are included in our offer.

- NextPCB can respond to your enquiry for a quote how long does it take?

- For nextPCB purchasing process we are responsive with great attention in providing prompt quotes to our customers. Normally we may require 24 hours to give an estimate of the project that you had sent us.

- Does NextPCB come with a mode for expediting the production?

- Clearly, NextPCB knows how important short production time is in the electronic industry (electronics field). They are furnished with fastprocessing technology for both prototypes and mass production runs that gives them better edge to handle late orders.

- Can NextPCB development team do the job for you?

- Absolutely. For clients who need prototypes specific to them, NextPCB has a wide range of customization options available to meet the design requirements. Tailoring your project to your company’s exact needs is their passion; from custom made materials to the last finishing touches and floor plan design, they will make your vision come true.

- What are the QC techniques of NextPCB?

- NextPCB pays highest attention to quality while it is processing the order of PCBs. They invest into the implementation of strict quality control methods at every level, such as inspections of materials, fabrication, and final drive test of each PCB (printed circuit board) to make sure that they satisfy or even surpass the industry norms.

- What are the applied measures besides the safety of the data and confidentiality of the information of the NextPCB?

- Finally, nextPCB will secure and confidential clients’ data. They adopt security policies and confidentiality docus with the help of these they ensure protection of the secret information during the process of production.

- NextPCB customers are typically from industries ranging from medical to aerospace and defense, therefore, focusing on finding customers is a paramount task for our marketing strategy.

- NextPCB offers services to a wide selection of industries including telecommunications, automobiles, airlines, medical devices and a wide variety of consumer electronic devices. They offer services with wide variations designed to satisfy every sector’s need.

- Is NextPCB a company which attends to environmental protection in the course of its entire manufacturing processes?

- Yes, NextPCB intends to consider the environmental issues among its top priorities as well. Ecological requirements conforming to the best practices and wherever possible green activities are adopted to curtail their carbon footprints.

Also read: How PCB Manufacturing is Done Successfully: 5 Key Steps