Prototool may occasionally advise you to use our factory’s two-color injection molding technique to complete your specific products, but if your deadlines are flexible and you’re looking to save money, we might advise over-molding service instead.

Overmolding is a fairly developed injection moulding technique in the market. To make your products successful in the market, our qualified personnel will offer you advice based on our nearly ten years of injection molding experience.

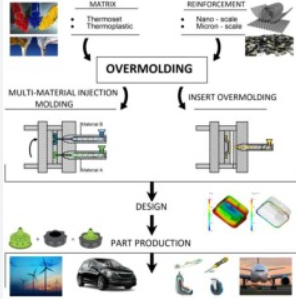

Types of overmolding techniques

There are various over-molding procedures, and each has a unique set of uses. The most typical kinds of over-molding constructions are listed below:

Regular use of plastic

Here, a stiff plastic substance is formed before being covered with yet another rigid plastic. These polymers come in a variety of hues, forms, and resins.

Rubber Over Plastic

A hard-plastic substance must be molded in this situation. After being formed, this plastic is then covered in TPE or soft rubber.

Plastic Over Metal

A metal substrate is first made, cast, or machined. The plastic is then molded around or over the metal, after it has been placed within an injection molding tool.

Metal Over Rubber

A metal substrate is first made, cast, or machined. The rubber or TPE is then molded over or around the metal after being placed into an injection molding tool.

Depending on the shape, complexity, and needs of your project, we provide a wide selection of materials for over-molding projects. Categorizing materials like rigid plastic, flexible plastic, and rubber plastic.

Under the structure of the mold, the interior has a standard, non-cosmetic finish.

An SPI Finish

SPI offers a variety of finishes, ranging from Grade 3 diamond/high polish to 320 stone/low polish. These finishing possibilities include SPI A-1, A-2, A-3, SPI B-1, B-2, B-3, SPI C-1, C-2, C-3, and SPI D-1, D-2, and D-3.

Threaded Inserts

The most popular and widely used standard inserts are available for installation in UNF and metric sizes.

As Molded

The mold will be left ‘as is,’ as the name implies, without any additional texturing or polishing.

Texturizing mold

Adding textures to the molds so that they show through in the finished product. The matte, swirls, patterns, and lines are part of this finishing option.

Laser Engraving

Engrave component numbers, artwork, logos, or any other printing according to your specifications using laser technology.

Pad Printing

applying a surface-based design made of ink.

Painting

Paint the surface, including primer and finish, in common colors or Pantone matches. There is EMI (copper) paint for masking.

What is overmoulding?

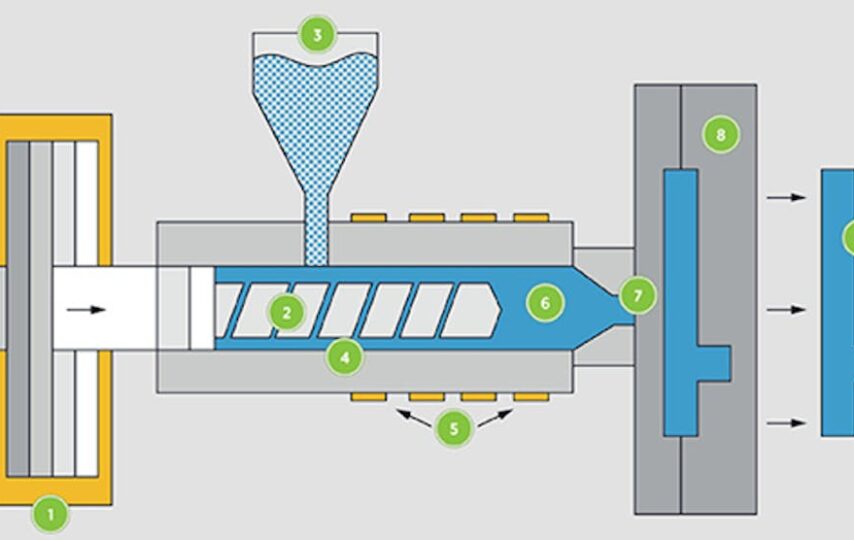

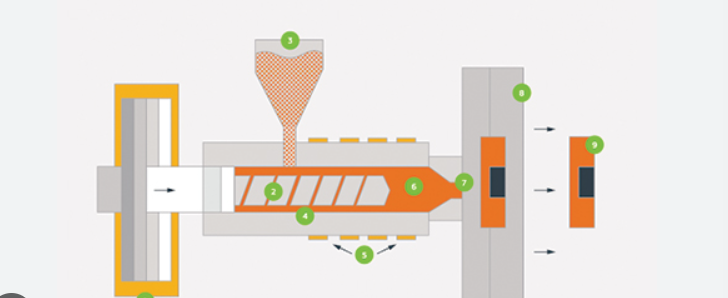

Overmoulding refers to the manufacturing process of a single part, which is created using two or more different materials in combination with each other. Typically the first material, sometimes called the substrate, is partially or fully covered by subsequent materials, sometimes called the over mold materials, during the manufacturing process.

It is when one thermoplastic material is molded over another material to form one integrated part of high-quality and better resistance.

It is extremely cost-effective because once the mold is made, it may be used numerous times to produce as many pieces as feasible. Additionally, over molding lowers labor and assembly expenses.