Thermoforming is a manufacturing process that involves heating a plastic material to its softening point and then forming it over a mould. This process is used to create a wide range of products, from disposable food containers to automotive parts. It is an ideal solution for small-scale manufacturing as it is cost-effective, versatile, and requires a relatively small investment in equipment. In addition, the use of a CNC machine can enhance the precision and accuracy of the thermoforming process.

Let’s talk about the benefits of thermoforming and how it can be used in small-scale manufacturing. Whether you are a small business owner or a product designer, this guide will provide valuable information on the use of thermoforming in your manufacturing process.

Advantages of Thermoforming for Small-Scale Manufacturing Units

For small-scale manufacturing units, thermoforming offers several advantages, including:

- Cost-Effectiveness – Thermoforming is a relatively low-cost process, compared to other manufacturing methods. The tooling costs for thermoforming are relatively low, making it an affordable option for small-scale manufacturing units.

- High Production Speed – Thermoforming is a fast and efficient process that can produce large quantities of products in a short amount of time. This can help small-scale manufacturing units meet tight deadlines and produce more products in less time.

- Versatility in Design – A wide range of products can be produced in various shapes and sizes with thermoforming. This makes it a versatile option for small-scale manufacturing units. The process can be used to produce products made from a variety of materials, including plastic, foam, and cardboard.

- Eco-Friendliness – It is a sustainable manufacturing process that uses less energy and raw materials compared to other methods. This makes it an eco-friendly option for small-scale manufacturing units that want to reduce their environmental impact.

- Easy to Automate – One of the key advantages of thermoforming is that it is a highly automated process, which makes it ideal for small scale manufacturing. The automated nature of the process allows for consistent and high-quality products to be produced quickly and efficiently, without the need for manual labour.

Applications of Thermoforming in Small-Scale Manufacturing Units

- Food Packaging: Thermoforming is an ideal method for food packaging because it provides a secure and hygienic environment for food products. It’s used for creating trays, clamshells, and containers that are used to store and transport food items. The process is also used to create blister packs, which are used to package individual food items, such as candy, cookies, and other snacks.

- Medical Packaging: Thermoforming is a crucial process for creating medical packaging, which is used to store and transport medical equipment and supplies. The process is ideal for creating blister packs, which are used to package individual medical items, such as syringes, needles, and other medical devices. Thermoforming is also used to create trays and containers that are used to store and transport medical equipment and supplies.

- Consumer Goods Packaging: Thermoforming can be used to store and transport consumer products. It is used for creating packs, which are used to package individual consumer goods, such as toys, electronics, and other consumer products.

- Industrial Parts and Components: The process of thermoforming is used for creating industrial parts and components, which are used in various industries, such as automotive, aerospace, and construction. The process is ideal for creating various parts and components, such as brackets, clips, and covers, which are used in various industries. Thermoforming is also used to create custom parts and components that are designed to meet specific customer requirements.

Challenges in Thermoforming for Small-Scale Manufacturing Units

Here are some of the challenges that small scale manufacturing units may face in thermoforming:

- Tooling Costs – The cost of tooling can be a significant challenge for small scale manufacturing units. Tooling costs can range from simple dies to intricate moulds, making it difficult for small scale manufacturing units to justify the investment.

- Quality Control – Maintaining the quality of the products during the thermoforming process can be challenging for small scale manufacturing units. Lack of experience and expertise can lead to inconsistencies in product quality, which can negatively impact the reputation of the business.

- Design Limitations – One of the biggest challenges faced in small-scale manufacturing is the design limitations that come with the process. The design of the product needs to be optimised for thermoforming, and there may be restrictions on the size and shape of the product.

There are a few solutions that can help solve these challenges,

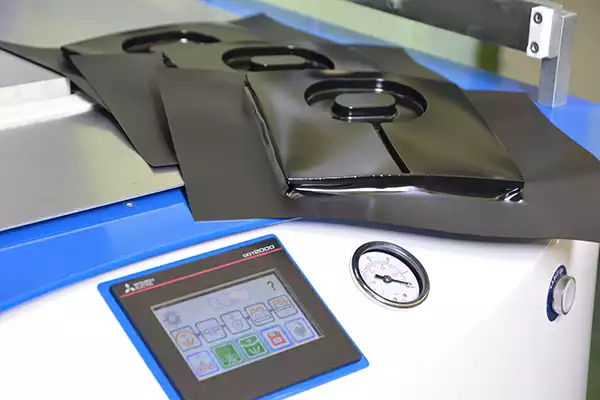

- Invest in High-Quality Equipment: Small scale manufacturers need to invest in high-quality thermoforming equipment to overcome production challenges. Good equipment will provide consistent results, reducing the chances of rejects and improving productivity.

- Train Employees: Small scale manufacturers need to invest in employee training to overcome operational challenges. Providing employees with the right knowledge and skills will help them to perform their jobs effectively, reducing the chances of mistakes.

- Standardise Processes: Standardising processes will help to overcome the challenge of inconsistent quality in small-scale thermoforming. A standard operating procedure manual will help to ensure that all employees follow the same steps and procedures, leading to consistent results.

- Select the Right Material: Selecting the right material for thermoforming is important to overcome production challenges. Manufacturers should consider the properties of the material, its cost, and its compatibility with the manufacturing process.

Conclusion

Overall, thermoforming is a versatile and cost-effective manufacturing process that is ideal for small-scale manufacturing. It allows for the creation of a wide range of products with a relatively small investment in equipment. Along with wood sanding machines, it is a valuable tool for small businesses and product designers seeking a reliable and efficient manufacturing process. Whether you are seeking to create high-quality products in-house or to bring your products to market faster and more efficiently, thermoforming machines are worth considering. These tools can help you take control of your manufacturing process and produce precise and high-quality products for your customers.